A partner in the heart of the extreme...

Thermo Est has developed know-how in temperature measurement that is recognized by researchers and industry alike.

Always ready to listen to its partners, Thermo Est participates in the development and improvement of knowledge in all fields of metallurgy, fluids and gases, where the best temperature measurement is essential. Thanks to their experience, Thermo Est engineers have succeeded in mastering all the welding and brazing processes that guarantee quality in the manufacture of temperature sensors. Rigorous selection and processing of materials, together with rigorous quality control, are the factors behind Thermo Est's international reputation.

- Remote handling in irradiated areas

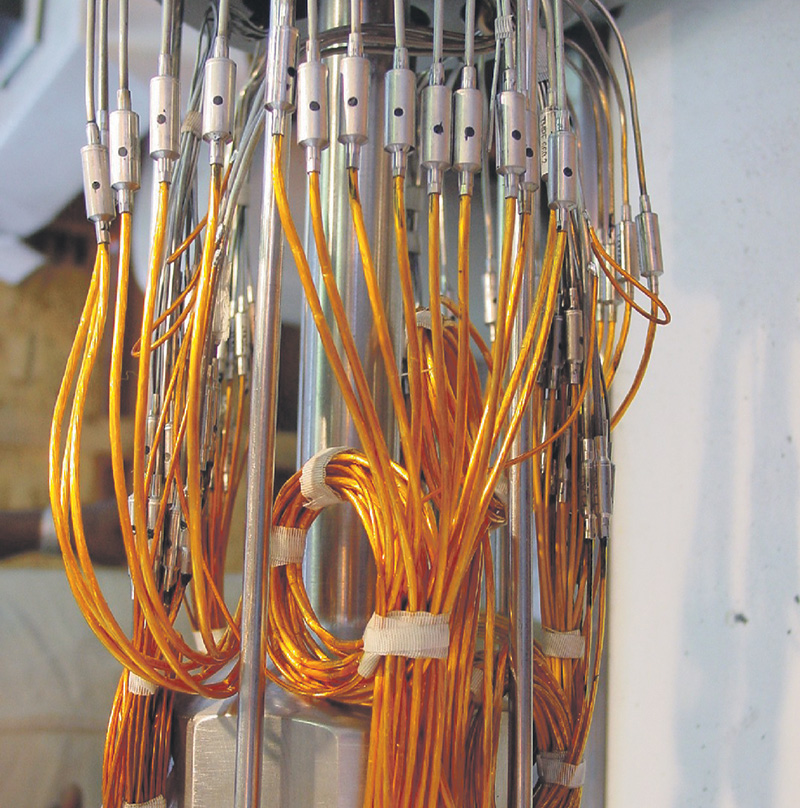

- Motor bearing, pump casing temperature

- Temperature water, steam

- Sodium level detection

- Pool temperature

- Mapping probe

- Melting pot (thermocouple conduit and cocoon)

- Heated collar

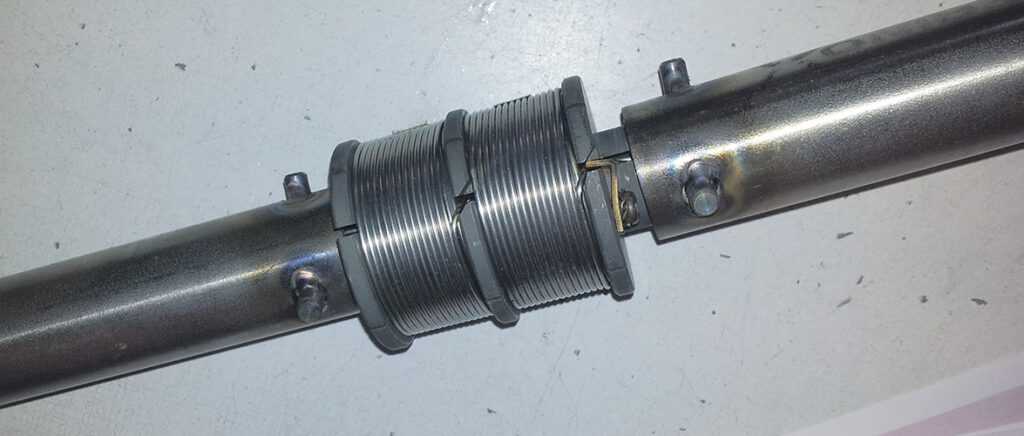

- Mineral-insulated transmission cables

High-temperature thermocouples type S, R, B, C or D

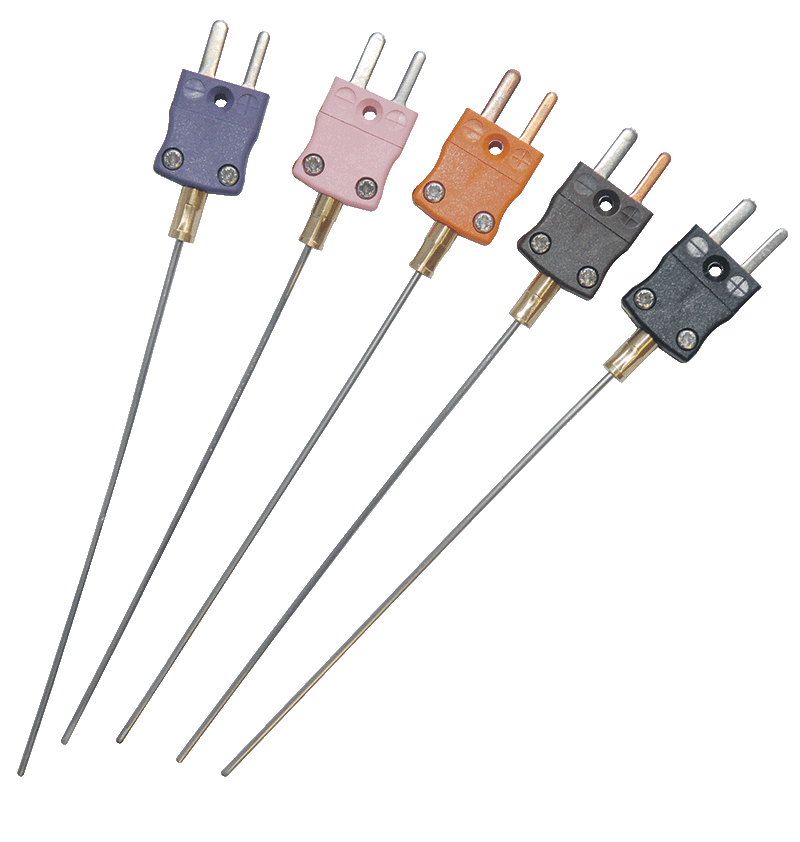

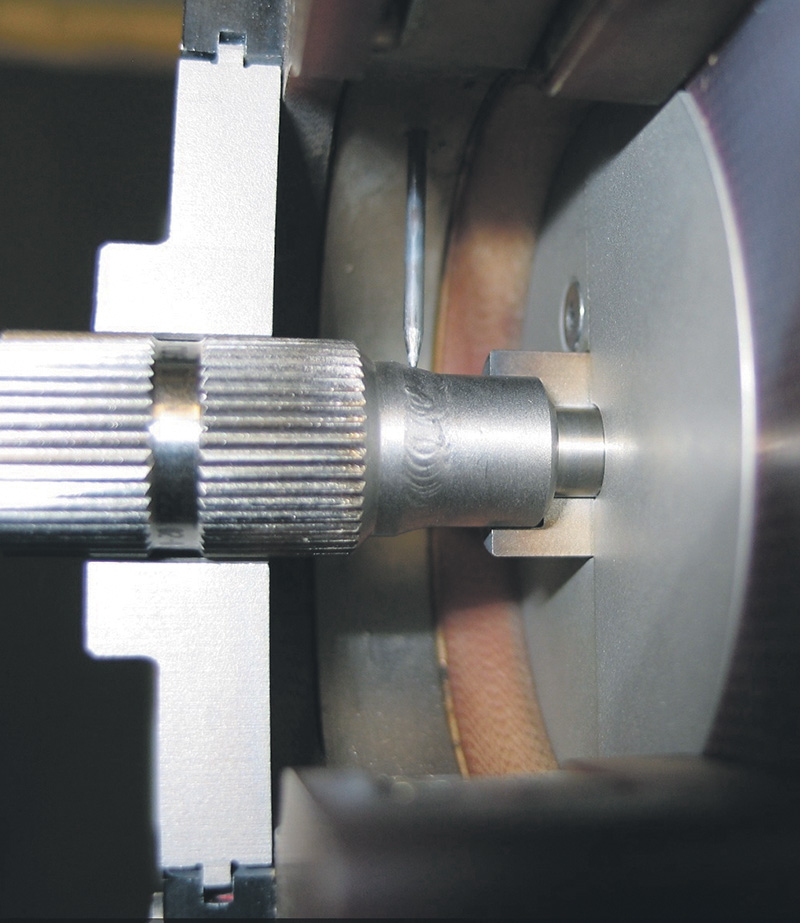

Known for their versatility as temperature sensors, thermocouples are manufactured in a variety of styles. Thermo Est's high-temperature sheathed thermocouples are used in applications where standard thermocouples don't meet the need because the temperature is too high. These thermocouples, made from high-purity materials and assembled by micro-welding in a neutral atmosphere, have seen their design evolve over time. The thermocouples used are of the S, R, B, C or D type, and are made with platinum wire of varying rhodium content, or with tungsten/rhenium wire. Standard insulation is MgO (magnesium oxide), also available with BeO (beryllium oxide), HfO2 (hafnium oxide), and Al2 O3 (aluminum oxide). A flexible or rigid metal sheath, such as molybdenum, tantalum, tungsten and rhodium-plated platinum, protects the assembly.

Qualified to withstand extreme conditions

- Compliance with demanding and complex standards

- Performance and technical expertise in extreme conditions

- Rigorous preparation of "RFF" qualification files

- Constant attention to the safety of people and installations

Means of control :

- Calibration - fixed points

- Stress calculation ASME PTC 19.3

- Isolation

- Line resistance

- Dielectric test

- Response time

- Helium test COFREND LT

- Penetrant testing

- PMI material test

- Leak test

- Pressure test

- Tensile test

- Vibrations, shocks, earthquakes

- Cobalt radiation

- Icing

Temperature

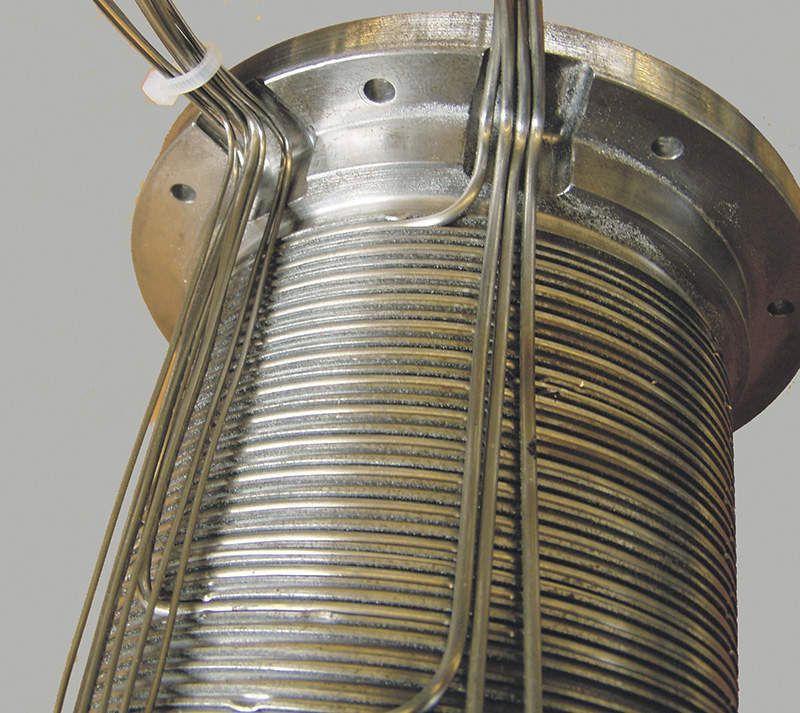

nuclear fuel elements

Pool water

Lorem Ipsum

Heating collars

Lorem Ipsum

Process temperature

Water, steam, engine bearing probe