Thermo Est develops heating solutions to meet your needs. This is achieved through the use of mineral-insulated shielded heating cables. Mineral-insulated shielded heating cables are characterized by their robustness, longevity and adaptability to extreme conditions. Thermo Est manufactures its own mineral-insulated sheathed heating cables to your specifications.

Exclusive range :

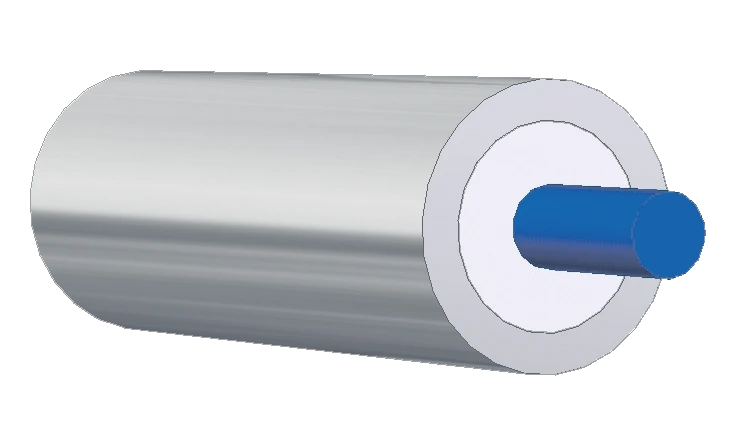

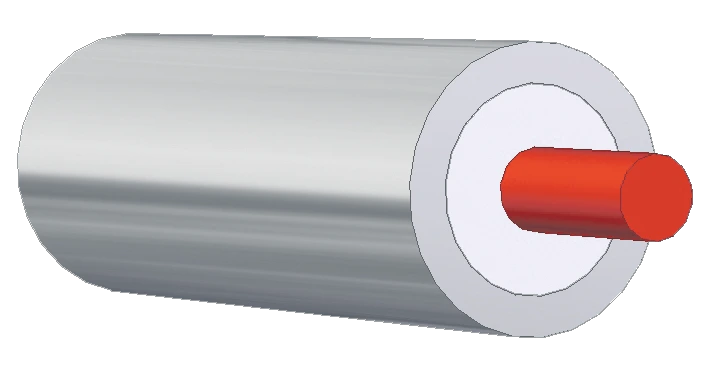

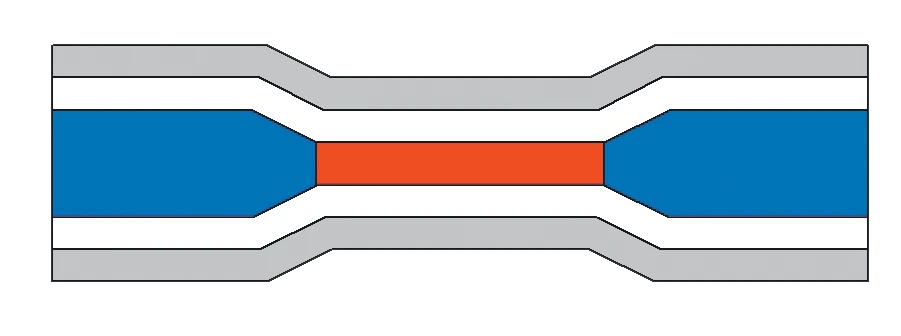

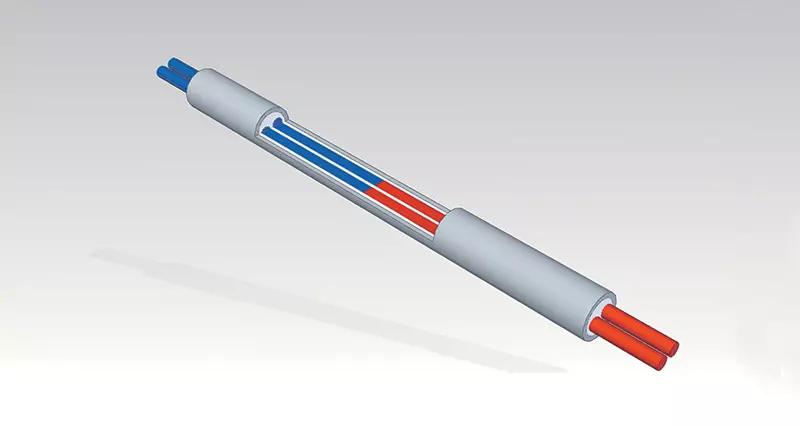

Construction of mineral-insulated heating cables :

Conductor for hot part :

- A NiCr 80/20, pure Ni or Balco® core

Core diameter depending on desired linear resistance - Double core NiCr 80/20, Ni

Conductor for cold end:

Copper conductor

Insulation:

Highly compacted "MgO" magnesia mineral insulation

Outer sheath :

- Diameter from 0.5 mm to 5.0 mm

- Variable supply voltage: e.g. 28 V, 115 V, 220 V or 400 VAC

- High insulation resistance

- Dielectric test at 1500 V

For temperatures up to +600°C: stainless steel AISI 321, 316 L ...

This type of sheath is highly resistant to corrosion in steam and gas environments. Used for continuous temperatures up to +800°C for applications in the chemical, food, automotive, research and development and nuclear energy industries.

For temperatures up to +1000°C: Inconel 600®

This type of liner has good corrosion resistance in oxidizing atmospheres up to +1000°C.

Resistant to corrosion and low electrochemical corrosion. Can be used in oxidizing atmospheres up to 1150°C. Not recommended in sulfurous atmospheres above 500°C for high-temperature applications in the chemical, food, automotive, R&D and nuclear power industries.

3 types of installation

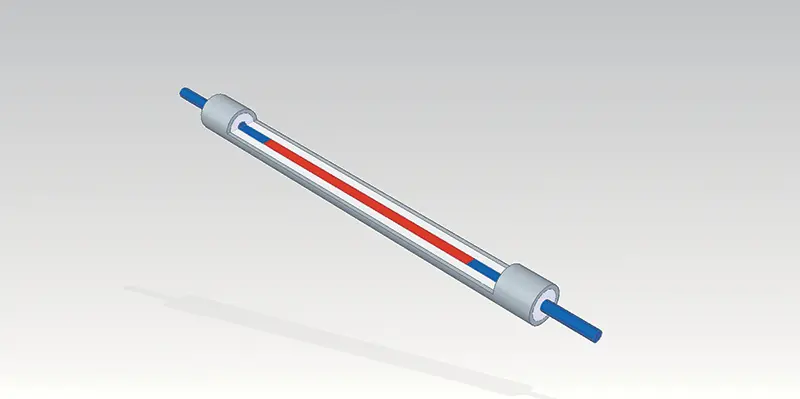

Raw version (sold by the meter)

Single- or two-core cable.

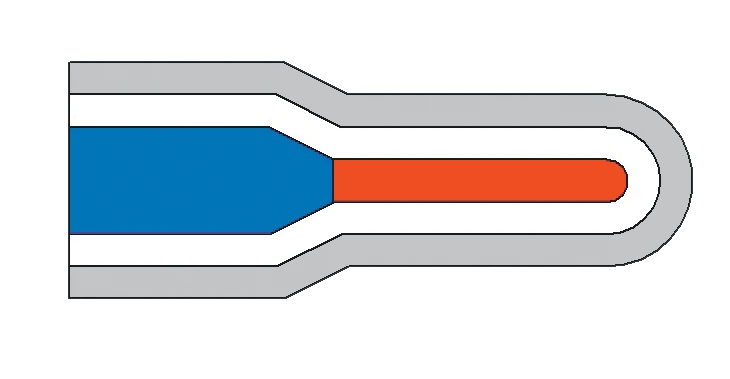

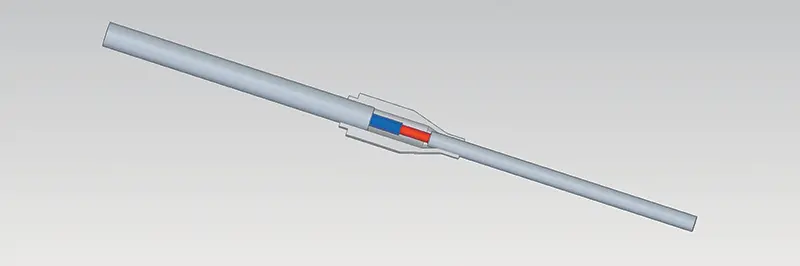

Tip swaged version

On single or two-wire cable, depending on swaging diameter, increases power by a factor of 2 to 4.

Length to your specifications.

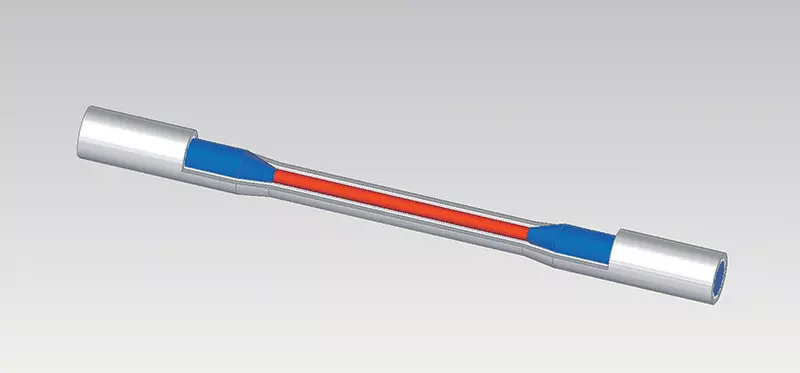

Central swaging version

This type of cable is available with swaging on the hot cable or swaging on the hot cable with built-in cold terminations.

Depending on the diameter of the swaging, power can be increased by a factor of 2.

Length according to your specifications.

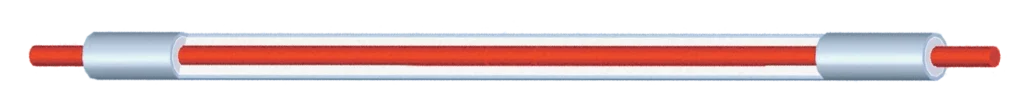

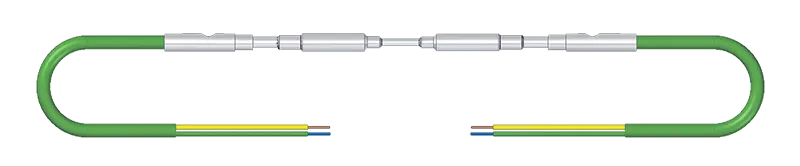

Heating cables with cold leads

Heating cables with integrated cold leads for constant diameter

Heating cables with laser-welded or soldered joints

Heated cables with swaging and integrated cold leads

Bi-conductor heating cables with integrated cold leads

Mineral-insulated shielded heating cables can be used in a wide range of environments, thanks to their robustness and adaptability to extreme conditions. For example, they can be used in a vacuum.

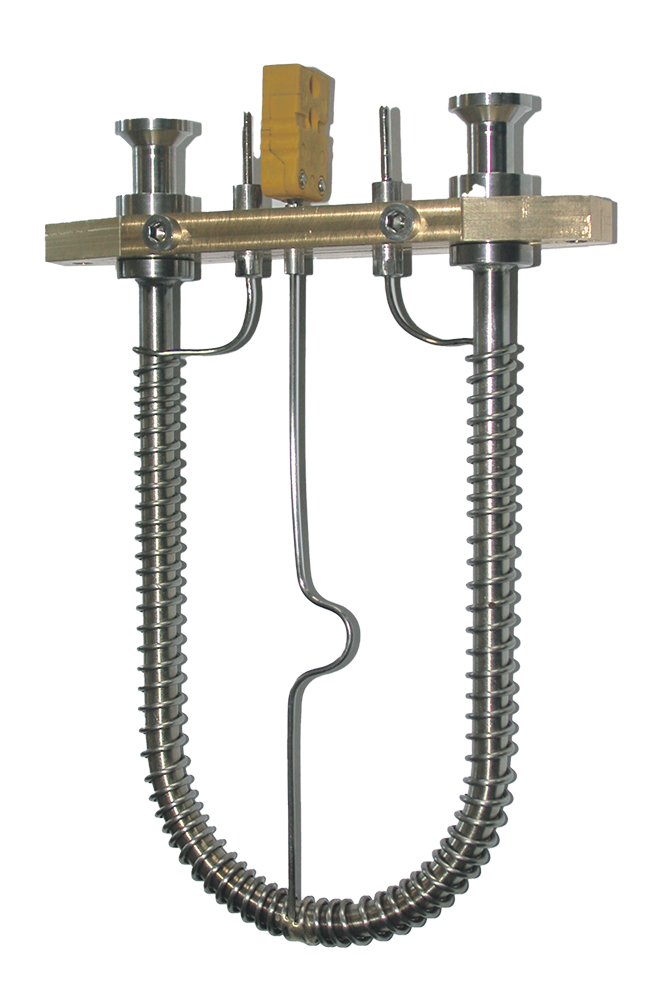

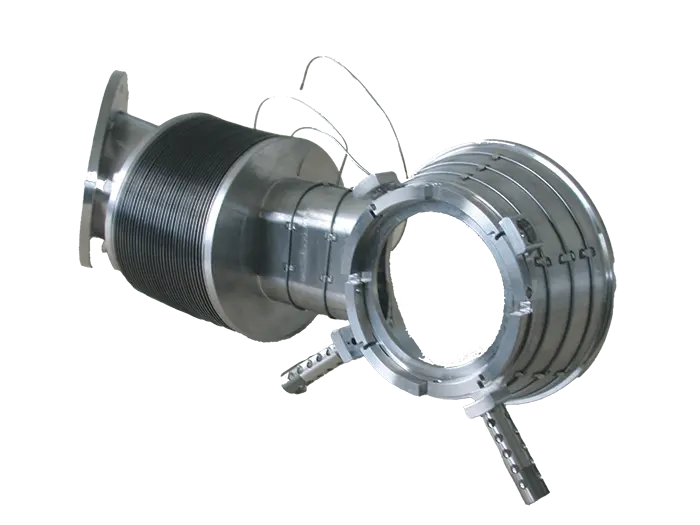

Application examples for your heating tools

From complex applications to industrial production runs, Thermo Est designs the heating solution to suit your needs.

From a few milliwatts to a few kilowatts, and for temperatures up to +1000°C, with small-diameter, mineral-insulated heating cables that are highly flexible and robust.

Our sheathed cable assembly methods vary according to the heating power required. The higher the temperature, the better the heat transfer. All our Thermo Est cables can be coiled, embedded or brazed, depending on their type, to suit all types of installation.

Example of coding for Thermo Est applications:

1 - I - NC - 0.63 - 4.3 - 5000 - 2x - DL - 1 - I - Cu - 0.007 - 4.9 - 2000 - 2x - D - T - 2.5 mm² - 1 m

Example: single-core heating cable

- Sheath: "I" (Inconel 600®)

- Core: NiCr 80/20, line resistance: 0.63 Ω/m

- Sheath diameter 4.3 mm, length hot section LC = 5000 mm two laser-welded joints 2x DL

- Cold parts "I" sheath (Inconel600®), copper conductor, line resistance 0.007 Ω/m

- Sheath diameter 4.9 mm, cold end length LF = 2000 mm

- Electrical termination: 2x D by non-detachable junctions with Teflon®-insulated copper wire L cable =1 metre - s=2.5 mm².

- P=3840W +/- 10% at 110 V

Puissance de chauffage <100 W / m ou jusqu’à 3 W / cm²

Aucun contact direct avec le câble chemisé n’est nécessaire pour les basses températures, de sorte qu’il suffit de fixer le câble chemisé à l’aide de bandes métalliques soudées par points.

Puissance de chauffage <300 W / m ou jusqu’à 6 W / cm²

Pour des températures plus importantes jusqu’à +600°C, il est important que le câble chemisé soit appliqué sur toute la longueur avec un très bon contact thermique entre deux plaques, brasé ou placé dans des rainures.

Heating capacity from 300 W / m to 1 KW / m or> 6W /cm²

For very high temperatures, optimum heat transfer is required over the entire length and surface. It's ideal if the jacketed cable is placed in grooves and then vacuum-brazed, or if it's sealed directly into a mechanical part.